3d printing and water monitoring….Huh ?

3d printing and water monitoring….Huh ?

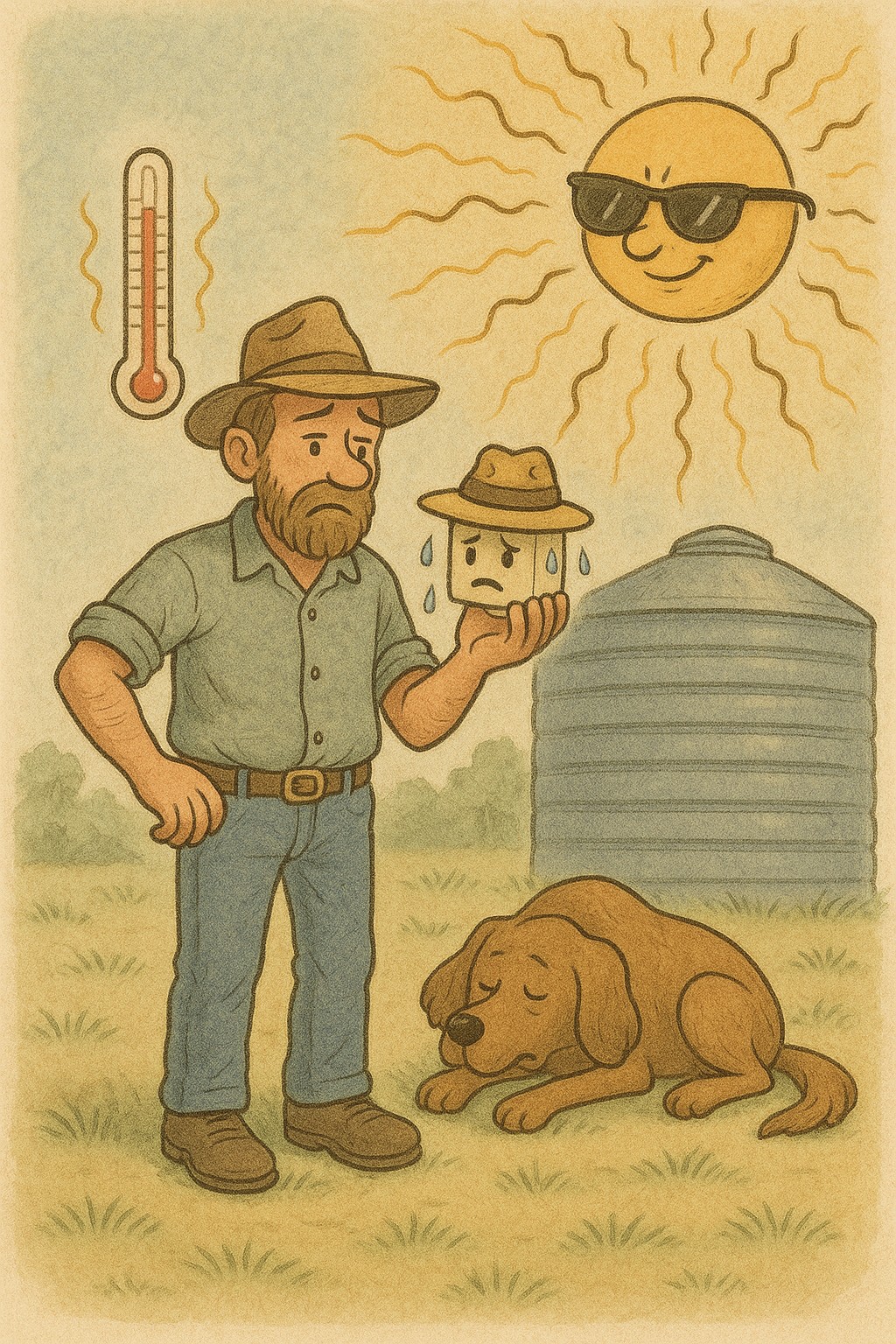

You’ve probably noticed that AquaVigil doesn’t arrive in a glossy injection-moulded shell that looks like it came off a conveyor belt somewhere overseas. Instead, the case is 3D-printed. That’s deliberate — and it isn’t about being trendy or “maker chic.” It’s about engineering for the real world, especially the Australian version of it, where summer sun can make the top of a water tank hotter than the sun!

The biggest reason Im using 3D printing is heat mitigation. When you design a case from scratch, you can shape it tightly around the electronics, keeping the overall footprint small and the exposed surface area minimal. Less surface area means less heat absorbed from the sun, which means happier electronics and far less battery stress.

And unlike mass-manufactured cases, 3D printing lets me cheat physics a little. The walls can be thicker without turning the whole thing into a brick, because the inside doesn’t have to be solid. Using around I get the printer to fill the inside wall with less than 10% plastic, which creates a sort of built-in heat barrier — a lightweight insulation layer that slows heat transfer. It’s like giving the electronics their own tiny besa brick wall.

Of course, some customers like to mount their AquaVigil on the top of a hot black poly tank somewhere out the back of Birdsville, where the sun isn’t joking around. For those brave souls, there will soon be a Sun Saver accessory on the way: an extra layer of heat shielding designed similar to a atmospheric temperature station for when the environment is doing its best impression of a blast furnace.

The second big advantage of 3D printing is iteration. When you’re designing something new, especially a system made for harsh environments, you learn fast. You learn even faster when customers start using it in ways you never imagined. If I need to tweak convection airflow, add mounting options, improve cable routing, or reinforce a corner, I can update the design the same day. No waiting for tooling changes. No minimum order of 10,000 units. Just quick progress — one print at a time.

There’s another benefit hiding in plain sight which I adore, and that’s repairability. If someone drops their unit off a tank, or a cockatoo decides the antenna looks delicious, I can print a replacement part without you needing to toss the whole device into landfill. A broken bracket doesn’t have to become a broken product.

And finally, 3D printing keeps production local. No factories. No shipping container delays. No “arriving sometime between next month and never.” It means AquaVigil can grow organically, improve constantly, and stay grounded in the real needs of the people using it.

In the long run, and if this venture works out, there will probably be an injection-moulded version — once the design stops evolving. But right now, 3D printing gives AquaVigil something mass production can’t: adaptability, durability, and a case that’s built for Australian heat instead of pretending it doesn’t exist.